for the treatment of handles, arm rests, seat backs or trims

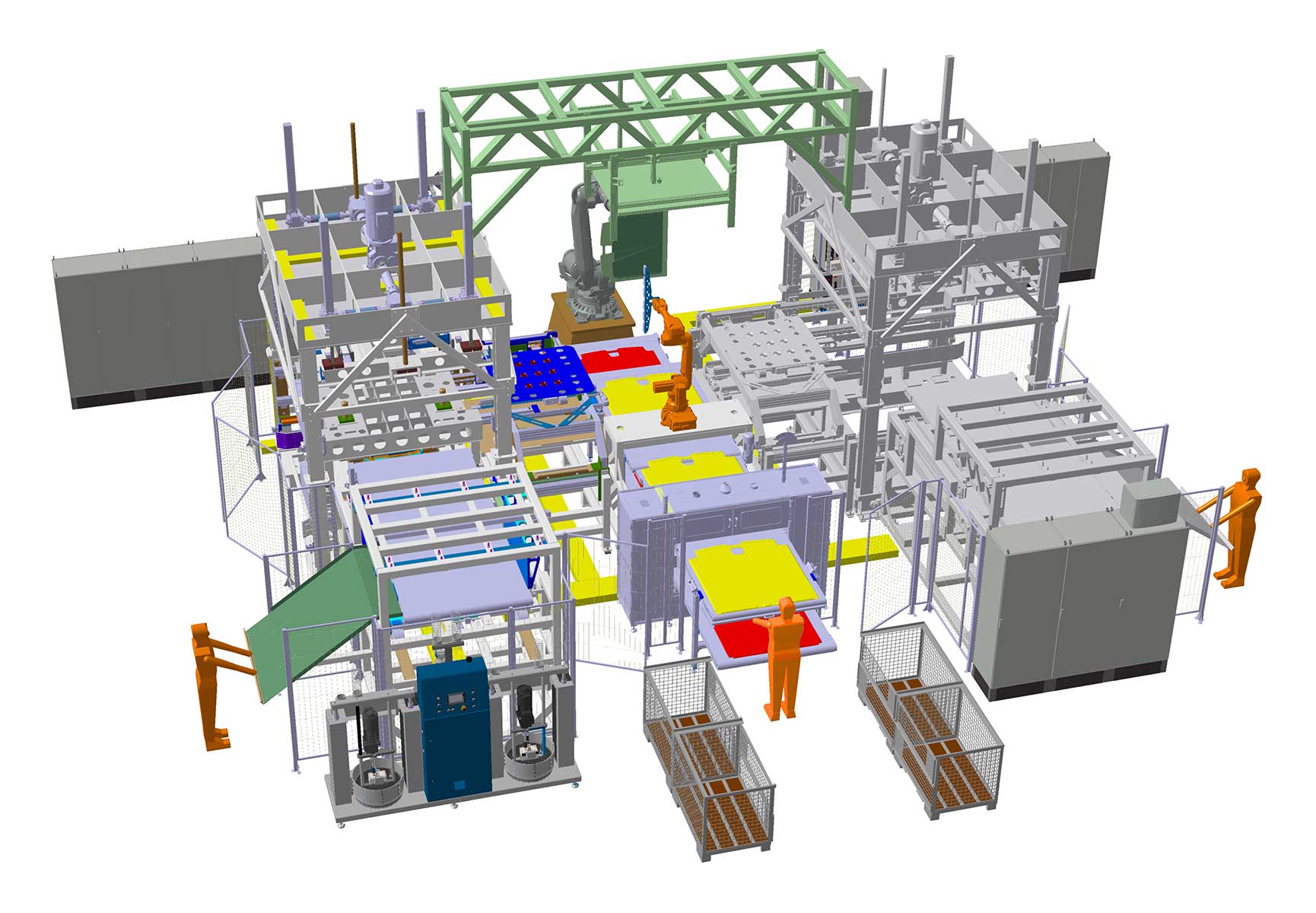

On all five continents, vehicle manufacturers use our compact and modular designed lamination technology. A tried-and-tested system design. material-saving concepts, automated processes and quick-change systems for maximum possible utilization make the highly reliable and low maintenance systems and tools from AKE-technologies a benchmark in the lamination sector.Lamination system for loading floors

System description

- Compound system for mounting and processing loading floors in the trunk

- Assembly system with integrated press system and exchangeable tools

- Production of various component variants possible

Processes

- Free insertion of fabric decor and carrier part and automatic position detection by camera systems

- Plasma treatment of the folding area of the carrier part

- Application of a hot melt adhesive by means of a roller system

- Heating of the adhesive by an infrared heating field

- Laminating and edgefolding process integrated in exchangeable tools

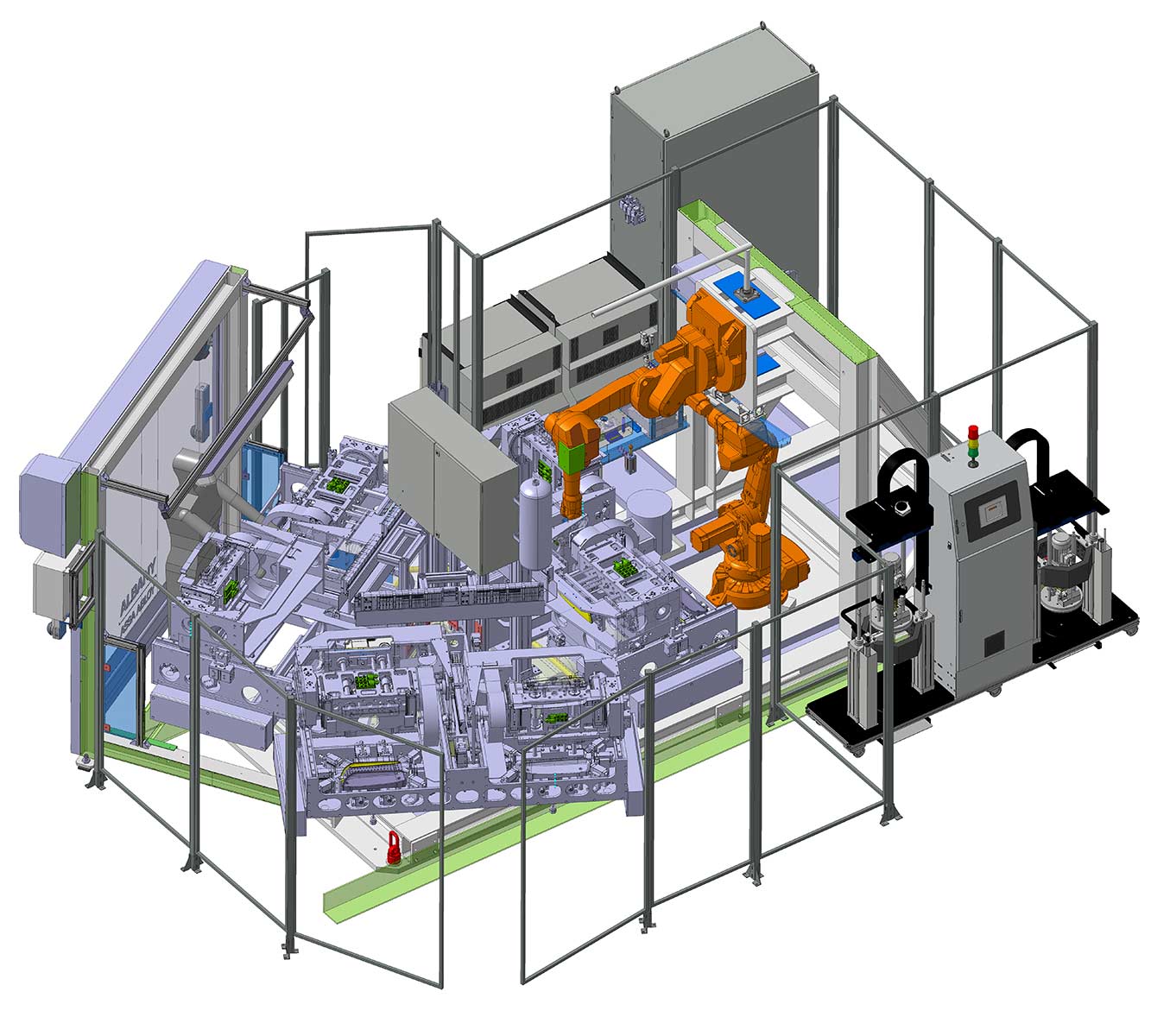

Gluing-Laminating-System for center armrests

System description

- Bonding of the fabric decoration instead of a complicated stapling process

- Inserting and positioning of the leather decor by the worker with the help of positioning aids

- Integrated plasma pretreatment

- Fully automatic gluing and edge folding

- Additional gluing of a cover

- Integrated adhesive application for gluing, laminating and edge folding processes

- Re-work-free edge folding

- Removable tool

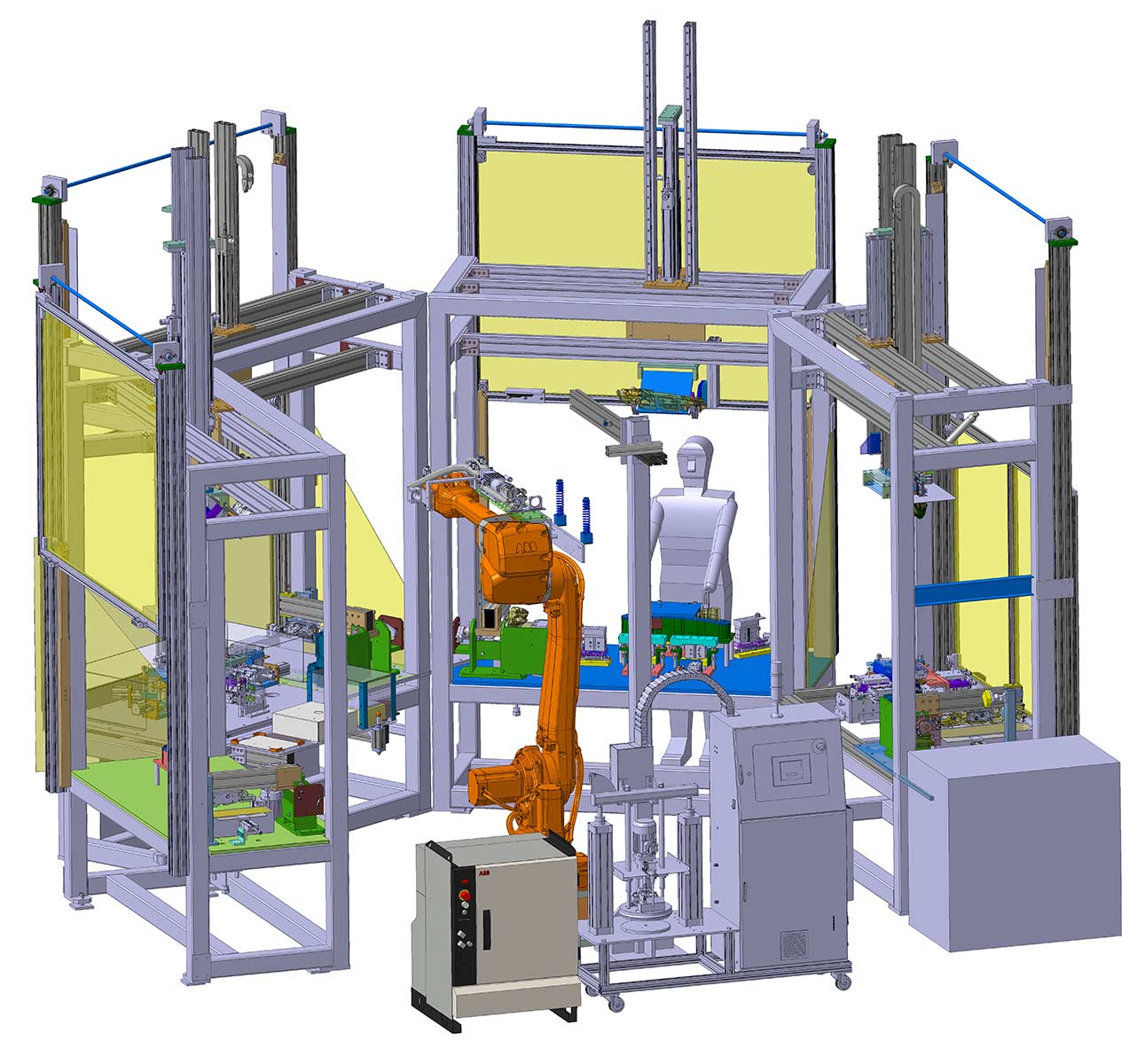

Lamination system with edgefolding process

System description

- Flexible system concept with four separate lamination edge-folding stations

- Variable deployment of workers (up to 4 persons)

- Workplace protection through vertical roller door systems to exclude unintentional process interruptions by the workers

- Manual equipping of the arm rest base carrier on the upper tools of the press systems

- Manual placing of the spacer fabrics with insert templates in the foam bed

- Manual placing of the leather blanks in the laminating tool with positioning of the stitching by laser pointer and vacuum fixing

- Automatic adhesive application with robot system in a spinning spray process for fixing the spacer fabric and the stitching to the base carrier

- Subsequent automatic lamination process in both tool systems

- Automatic adhesive application applied as a bead for the downstream automatic edge-folding process

- Circulating rework-free edge-folding process of the component edge

- Separate monitoring of the adhesive equipment with cyclical checking of the output and tool alignment