With the assembly test systems from AKE, the manufacture and testing of hinges is possible in shortest cycle times. The system technology includes production systems for a wide variety of hinge types from numerous areas of application.

The product portfolio ranges from production systems for tailgate or front lid hinges for a wide variety of vehicle types to door hinges and kinematic systems for various industrial sectors such as automotive, white goods or the furniture industry.

The assembly lines of AKE technologies are designed for the production of different hinge types on one system. Depending on the type of system, the hinge bodies are inserted with the help of a worker or automatically. Small parts are provided via conveyor systems with an autonomy up to 4 hours.

semi-automatic assembly line for door hinges

System description

System description

- Compact design with accessible system platform

- Highly flexible assembly concept through combined workers and use of robots

- Quick-change component holder for type changes

- Integrated calibration station

- Torque test of bearing points

- 5 seconds cycle time for assembling and testing a door hinge

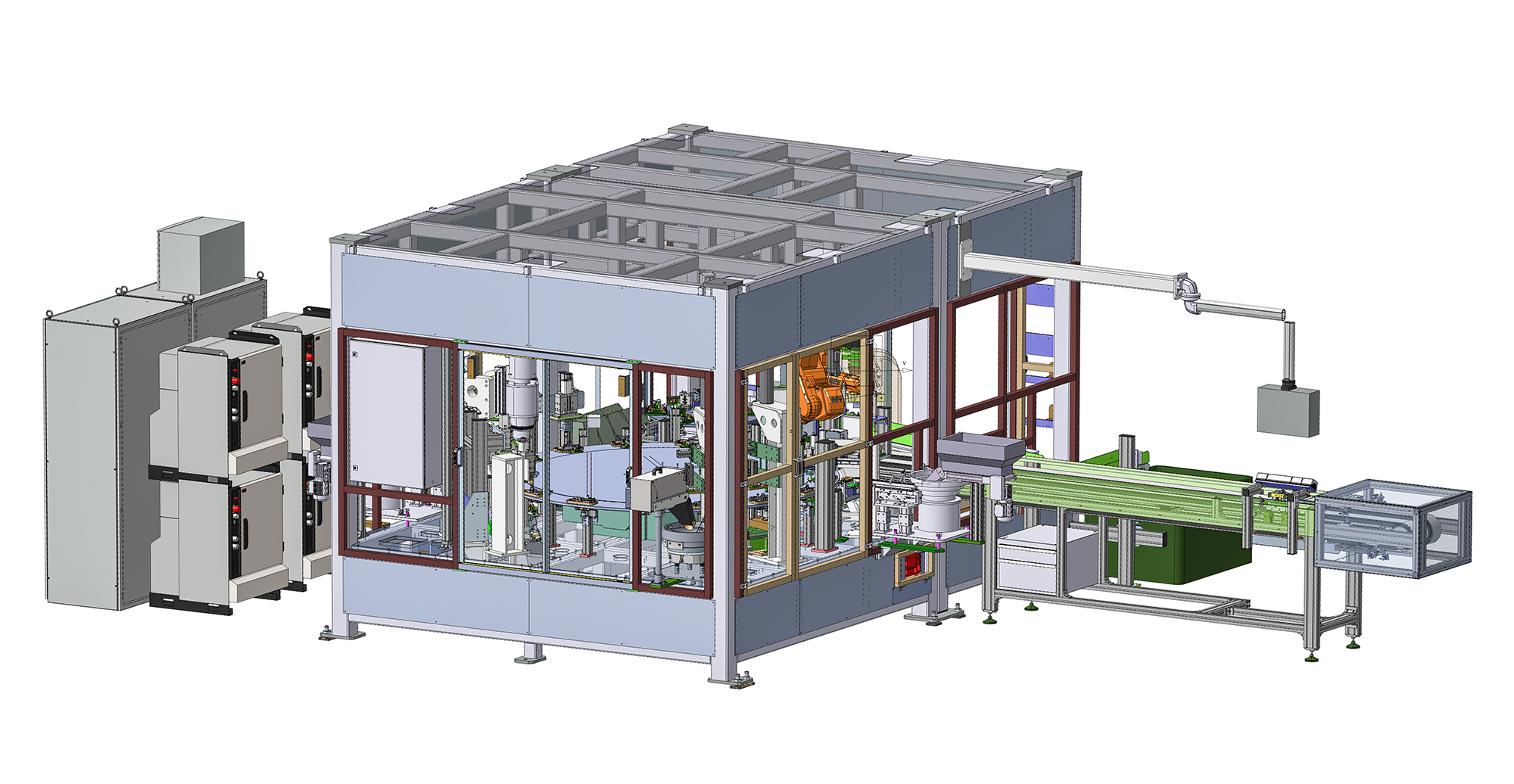

Fully-automatic assembly line for door hinges

System description

- Compact design with accessible system platform for control cabinets and hydraulic supply

- Flexible deployment of workers due to feeding systems with buffer function

- Parts handling by 6-axis robot

- Optical component detection and measurement by high-resolution camera systems

- 4.5 seconds cycle time for the assembly of one door hinge

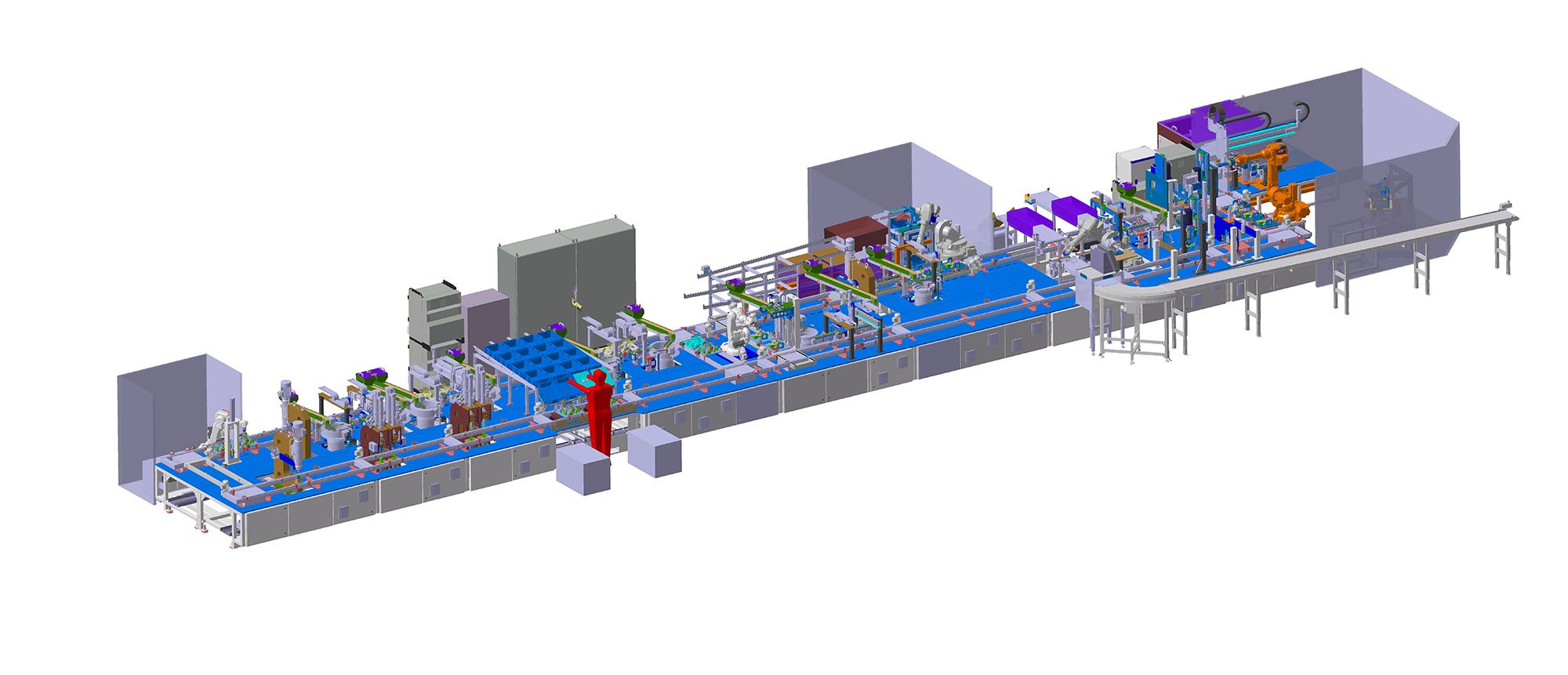

Assembly line for front lid hinges with active pedestrian protection

System description

System description

- Production of several hinge variants on one system

- Automatic feeding systems

- Integrated calibration station

- Setting up the delivery position of the hinge

- End of Line testing station with optical measurement

- 15 seconds cycle time for assembling and testing a front lid hinge with active pedestrian protection

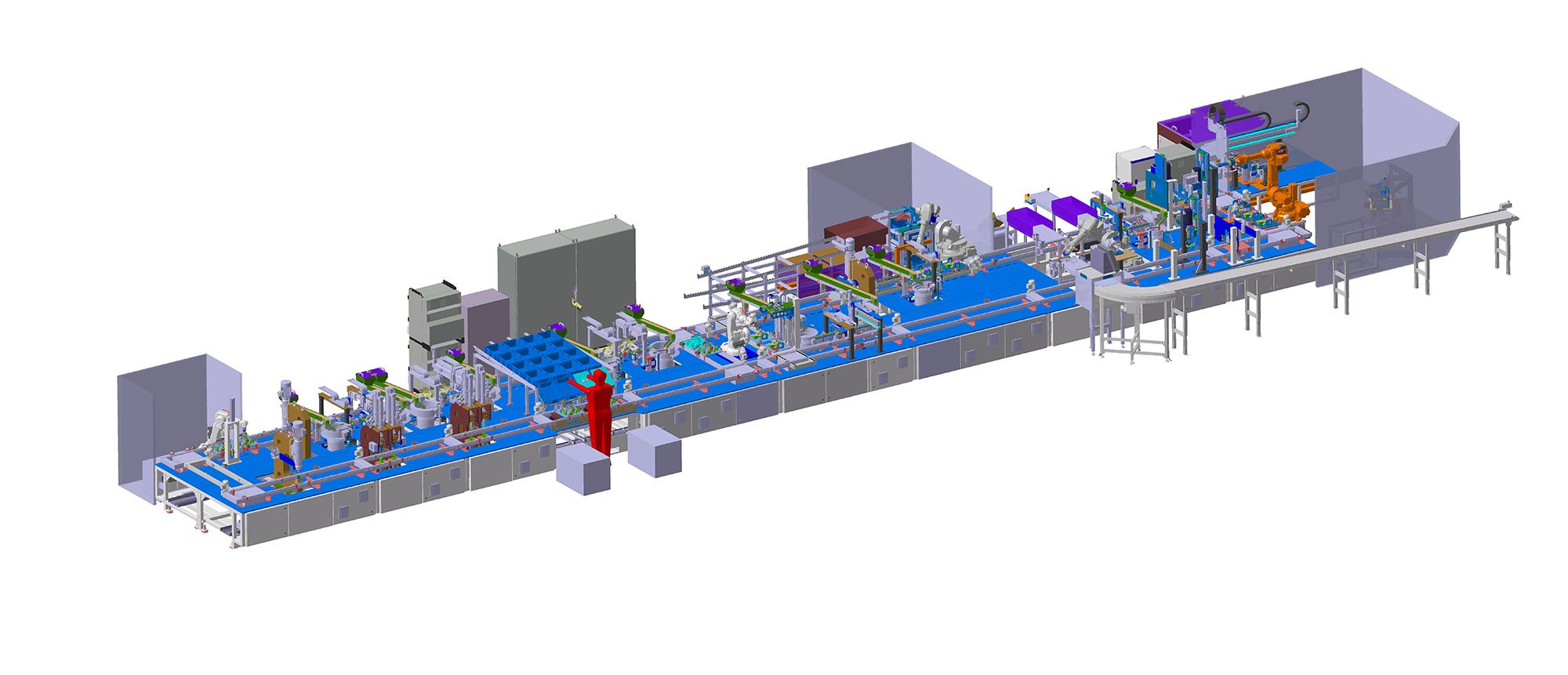

Assembly line for car trunk hinges

System description

System description

- Production of several hinge variants on one system

- Insertion of the hinge body in a rotary indexing table

- Bulk goods infeed from large load carriers

- Integrated calibration station

- End of Line testing station with optical measurement

- 11 seconds cycle time for assembling and testing a car trunk hinge

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

Learn more about production lines from the field of assembly and testing technology: