for the treatment of trims, armrests and seatbacks

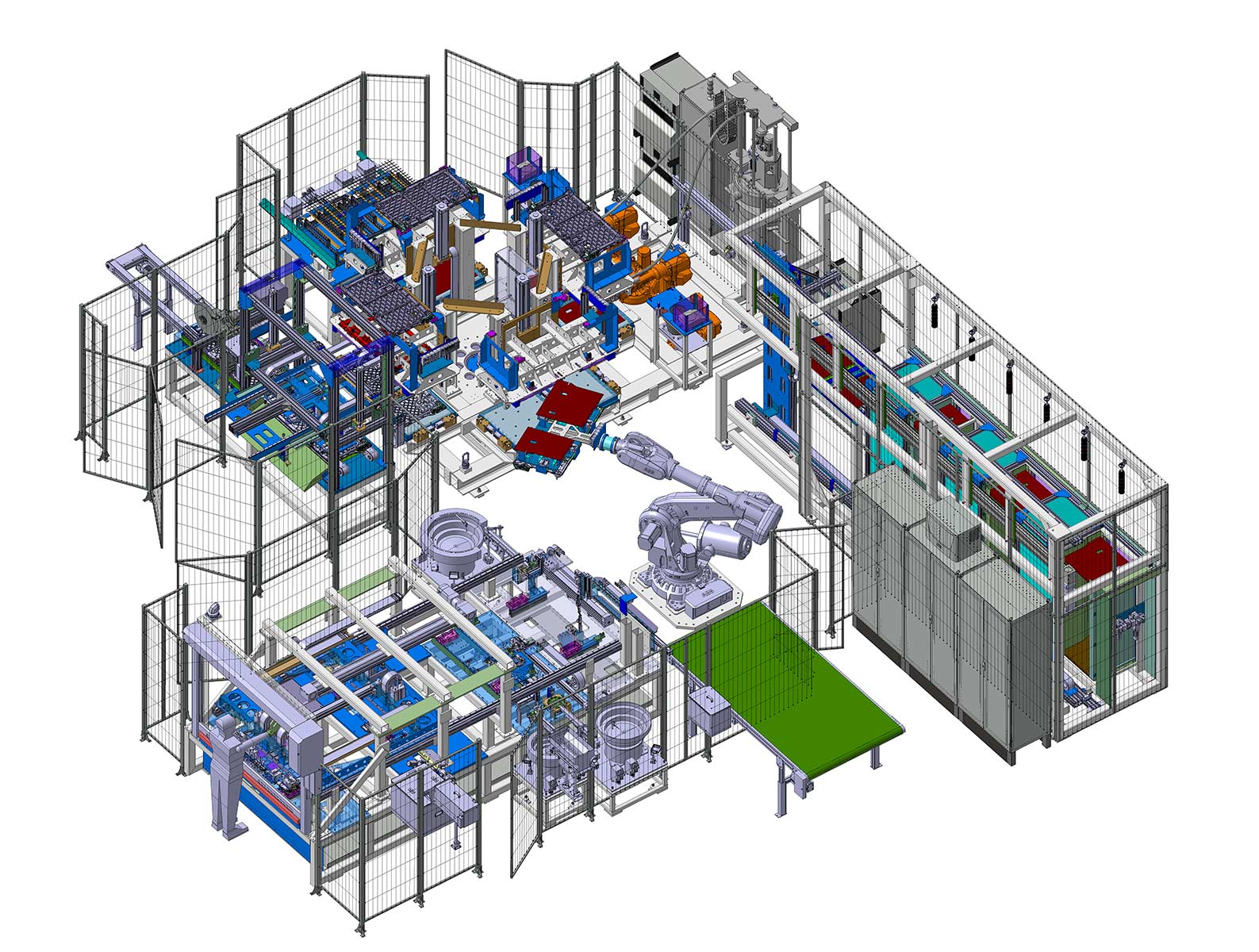

As a technology-neutral manufacturer, we provide our customers with gluing and joining systems in all required degrees of automation. We combine many years of experience with power of innovation and absolute customer orientation. Newly developed processes are tested at AKE-technologies for their practical suitability in an extensive series of tests. The output is always a product with the highest level of quality.Assembly-Laminating-Gluing System for the treatment and assembly of seat backs

System description

- System for fully automatic assembly of add-on parts on rear seat backrests and for sticking carpets on the seat back

- Inserting the metal structures and the backrest locks by the worker

- Automatic screwing of the backrest locks

- Automatic feeding and mounting of various bearing parts

- Picking up the carpets to be glued with robots from a magazine system

- Automatic insertion of carpets and metal structures into the rotary indexing table

- Apply glue to the carpets

- Heating and pressing of carpet and metal structure

- Automatic removal and component marking

- Documentation of all process data (torque and angle of rotation of screwing processes, carpet colors, temperature, amount of glue etc.)

- Automatic transport of all components during the entire assembly process

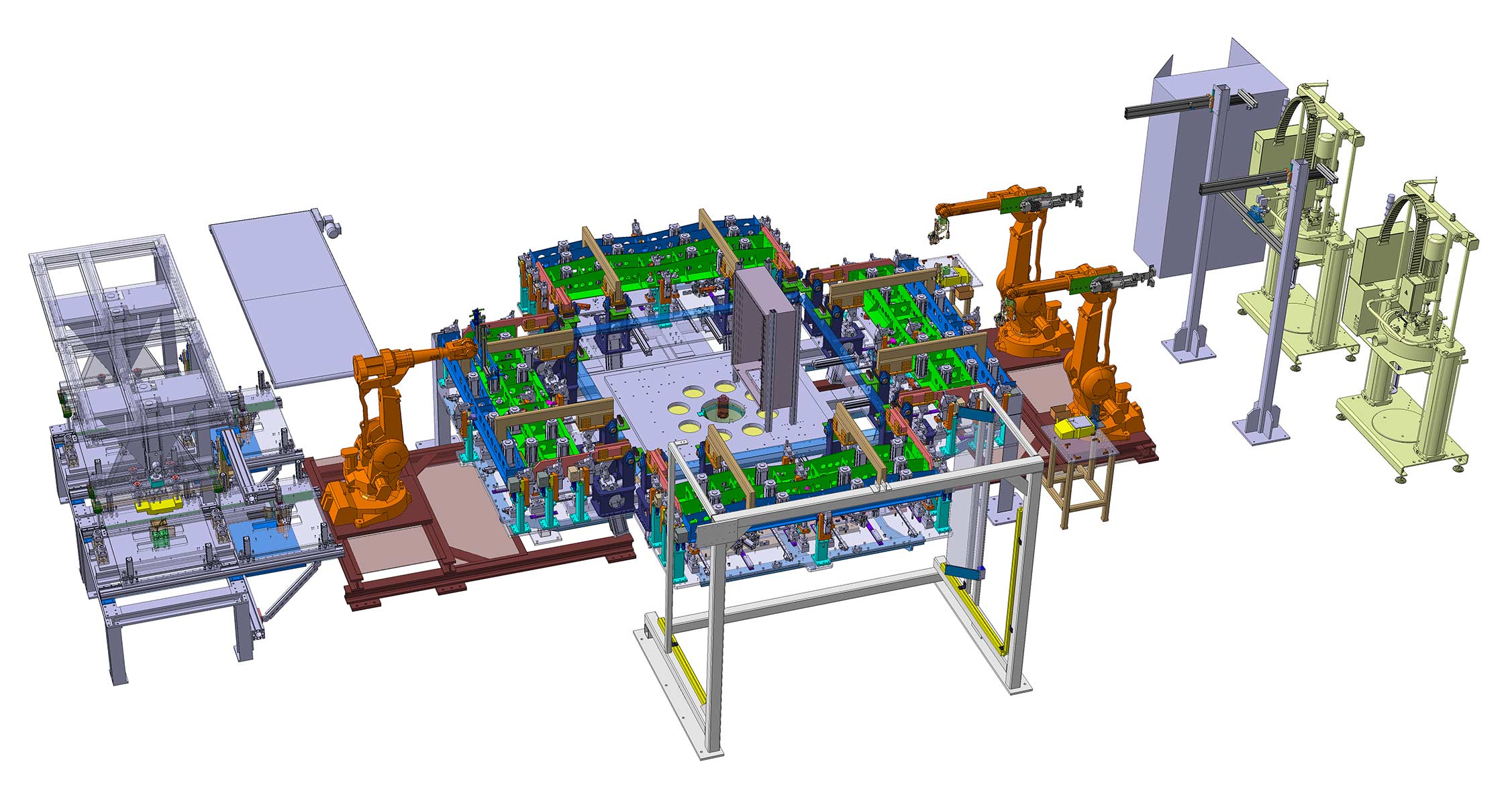

Gluing system for trim parts

System description

- System solution as rotary indexing table with four processing stations and parallel processing of two components to increase production capacity

- Workplace protection via contact-less light protection system with step-back guard for ergonomic workplace design

- Manual insertion of various components by the workers

- Tool systems with component mounting molds and bonding systems for attached components

- Component mounting molds with integrated parts detection and locating

- Automatic adhesive application with two robot systems applied as a bead for the downstream automatic jointing process

- Monitored jointing and cooling process of the glued joints

- Separate monitoring of the adhesive equipment with cyclical check of the output and tool alignment

- Automatic component removal with a robot system and transfer function to the downstream system for further processing