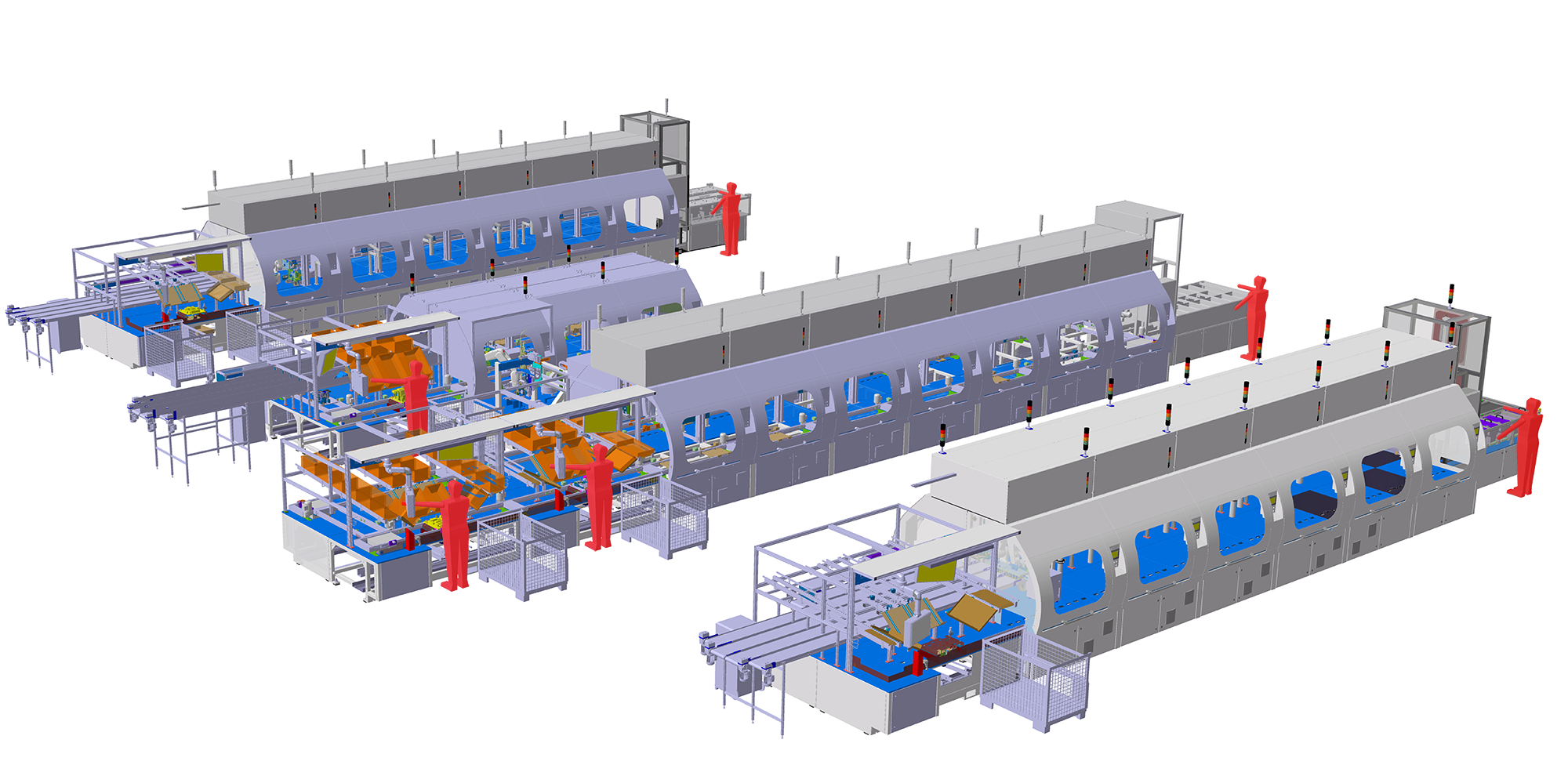

Assembly line for manual-automatic assembly and testing of power distribution systems

When designing assembly lines for Power Distribution Systems, the modular AKE standard cell is often used. Workpiece carrier systems, robotics and monitoring systems designed individually for our customers promise flexibility and individuality within the standard concept.

General information

- Possibility to combine manual and automatic processing stations

- Design as a fully automatic production line

- Connection to upstream and downstream systems such as injection molding machines

- Simple integration of additional processing stations in the event of changed specifications, quantities and component variants

- Connection of the stations with conventional transport systems such as double belts, but also with innovative shuttle and linear drive systems

- Complete data documentation and process monitoring

- Possibility of integrating a central material station to reduce logistics routes

Processes

Automatic process examples

- Feeding of various components (housing, fuses, washers, screws, nuts, ...)

- Camera testings as incoming inspection of components (e.g. overmolding inspection of surfaces)

- Screwing of attached parts

- Clinching of electric components

- Mounting of components with end position, maximum force or force-displacement monitoring

- Hot welding and ultrasonic riveting processes

- Insertion of pressure compensation elements

- Laser transparent welding of plastic parts

- Leakage tests

- Mechanical EOL tests (e.g. actuation of mechanical assemblies)

- Electrical EOL tests (e.g. continuity and function)

- Optical 2D and 3D EOL tests (e.g. latching and measurements)

- Component marking with labels, inkjet printers or laser systems

- Automatic packaging of the produced components in customer packaging

Manual process examples

- Assembly of individual parts

- Packaging of the produced components

- Assembly of connectors and cable assemblies

Scope of documentation

- Batch numbers of the individual parts

- Individual part tracing of safety-relevant individual parts such as electrical separator elements

- Mounting forces and paths

- Torque and angle of rotation values of the screwing processes

- Camera images and results

- 2D and 3D measurement results

- Test results from the EOL tests

- General information on the component such as the individual part number, production time, product variants, and much more.